Articles > Ruthenium Mining and Production

Ruthenium is a rare transition metal that is primarily mined as a by-product of nickel mining and processing. The extraction of ruthenium involves a complex process of crushing, grinding, and flotation to separate the nickel and copper ores from the ruthenium-containing materials. Once the ruthenium-bearing materials are separated, they undergo further refining processes, such as leaching and precipitation, to isolate the ruthenium metal.

Ruthenium is extremely rare, with an average abundance in the Earth's crust of only about 0.001 parts per million. This scarcity makes ruthenium one of the rarest elements in the Earth's crust. Its unique properties, such as its resistance to corrosion and its ability to harden other metals, make it a valuable material in various industrial applications, such as electronics, and as a catalyst in the production of chemicals and pharmaceuticals.

Overall, the process of ruthenium mining involves sophisticated technologies to extract and refine this rare and valuable metal, which is essential for various high-tech applications.

Ruthenium is a rare transition metal that holds great significance in various industrial and scientific applications. Its importance stems from its unique chemical properties, which make it an essential component in catalysis, electronics, and materials science. Ruthenium's ability to act as a catalyst in chemical reactions, particularly in the production of ammonia and petroleum refining, has proven invaluable in increasing efficiency and reducing environmental impact. In addition, its use in electronics, such as in thin-film resistors and magnetic storage devices, has revolutionized the technology industry. Furthermore, ruthenium's ability to strengthen alloys and enhance corrosion resistance has made it a vital component in the development of advanced materials for aerospace and medical applications. Overall, the importance of ruthenium cannot be overstated, as it continues to play a crucial role in driving advancements in various fields and industries.

Ruthenium holds significant importance in various industries due to its unique properties. In the electronics industry, it is used as a hardening agent for other metals, increasing their durability and resistance to wear and corrosion. This makes it an essential component in the production of electronic devices, such as semiconductors and electrical contacts.

In the technology sector, ruthenium is utilized in advanced technologies like 5G and AI. Its ability to withstand high temperatures and its electrical conductivity make it an ideal material for these cutting-edge developments.

In the field of medicine, ruthenium shows promising potential in cancer treatments. Compounds containing ruthenium have been studied for their anti-cancer properties, leading to the development of potential new drugs for cancer therapy.

Lastly, ruthenium is popular in jewelry for its unique dark color and durability. It is often used as a plating material for white gold and as an alloying agent for platinum, enhancing its strength and scratch resistance.

In summary, ruthenium plays a crucial role in various industries, contributing to the production of electronics, advancements in technology, potential cancer treatments, and the creation of durable and stylish jewelry.

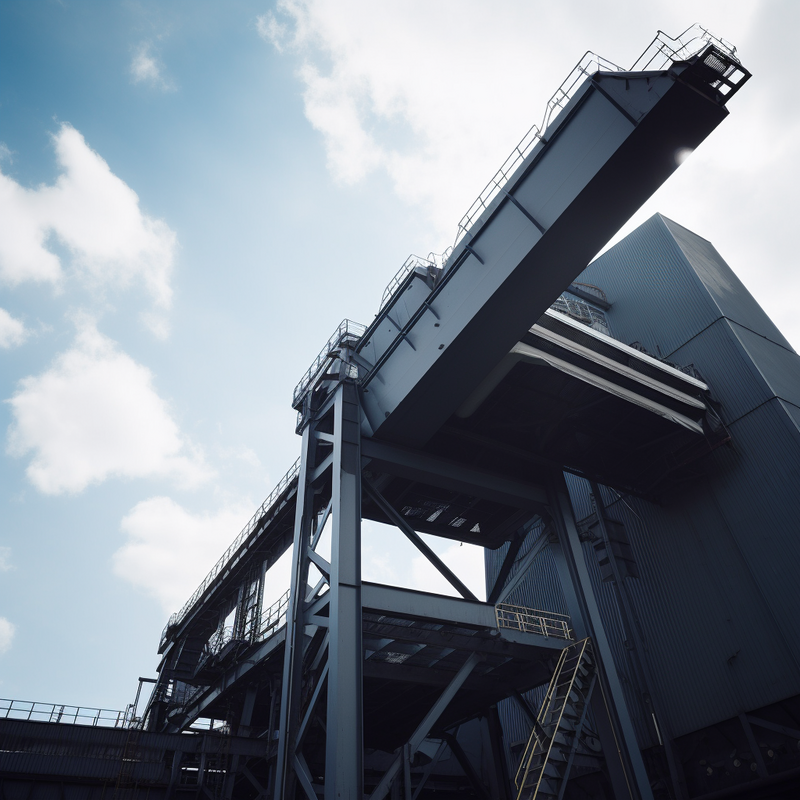

Ruthenium, a rare and valuable metal, is primarily mined as a byproduct of other metal extraction processes. Despite being one of the rarest elements on earth, ruthenium is becoming increasingly important in various industrial applications. However, the current state of ruthenium mining technology is relatively underdeveloped when compared to other metals. The extraction process for ruthenium is complex and requires sophisticated technology to separate it from other metals. As a result, there is a growing demand for efficient and environmentally sustainable mining techniques for ruthenium. This has prompted the exploration of new technologies and methods to improve the efficiency and sustainability of ruthenium mining. This includes the development of advanced extraction processes, such as solvent extraction and ion exchange, as well as the implementation of innovative mining practices that prioritize environmental conservation. Furthermore, research and development efforts are also focusing on finding new sources of ruthenium and improving the overall supply chain to meet the increasing demand for this valuable metal.

Ruthenium is a rare and precious metal that is primarily used in the production of high-temperature and corrosion-resistant electrical contacts and electrodes. As a result of its scarcity, the extraction of ruthenium is a complex process that requires advanced mining methods and techniques. In this article, we will provide an overview of the existing mining methods and techniques for ruthenium extraction.

One of the most common methods for ruthenium extraction is through traditional mining techniques, such as open-pit and underground mining. Open-pit mining involves the excavation of the earth's surface to extract the ore containing ruthenium. This method is typically used when the ore is located close to the surface and is cost-effective. Underground mining, on the other hand, involves the construction of tunnels and shafts to access the ore deposit. This method is used when the ore is located deep beneath the earth's surface.

In addition to traditional mining methods, advanced techniques such as in-situ leaching and solution mining are also used for ruthenium extraction. In-situ leaching involves the injection of a leaching solution into the ore deposit to dissolve the valuable metal. The solution is then pumped to the surface, where the ruthenium is extracted through a series of chemical processes. Solution mining, on the other hand, involves the injection of a solvent into the ore deposit to dissolve the ruthenium. The solution is then pumped to the surface and processed to extract the valuable metal.

Furthermore, hydrometallurgical processes are used to extract ruthenium from the ore. These processes involve the use of chemical solutions to dissolve the ore and separate the valuable metal from impurities. Once the ruthenium is separated, it is further purified through electrorefining or other refining techniques to obtain high-purity ruthenium.

It is important to note that the extraction of ruthenium is a complex and expensive process, due to the metal's rarity and the extensive mining methods and techniques required. As a result, ongoing research and development in the field of mining and metallurgy are focused on finding more efficient and sustainable methods for ruthenium extraction.

In conclusion, the extraction of ruthenium involves a variety of mining methods and techniques, including traditional mining, in-situ leaching, solution mining, and hydrometallurgical processes. Ongoing advancements in mining technology and metallurgy are crucial for the sustainable extraction of this rare and valuable metal.

As technology continues to advance at a rapid pace, it is important to have discussions about its limitations and challenges. While there are countless benefits to the innovations and advancements in technology, it is equally important to acknowledge the barriers that may impede its progress.

One of the primary limitations of current technologies is their reliance on infrastructure. Many technological systems require a robust and reliable infrastructure to function properly. This can pose a challenge in areas with poor or nonexistent infrastructure, limiting the reach and impact of technology in those regions. Additionally, the reliance on infrastructure can also make technological systems vulnerable to disruptions such as natural disasters or cyber attacks.

Another limitation is the issue of accessibility. While technology has become increasingly accessible to a larger population, there are still segments of society that are excluded from its benefits. This can be due to factors such as cost, lack of digital literacy, or physical barriers. Ensuring equitable access to technology is essential in order to bridge the digital divide and provide equal opportunities to all.

Furthermore, the rapid pace of technological advancements can create challenges in terms of adaptability and integration. As new technologies emerge, it can be difficult for organizations and individuals to keep up with the changes and effectively integrate them into existing systems. This can lead to inefficiencies and compatibility issues, hindering the full potential of the advancements.

In addition, there are ethical and privacy concerns associated with current technologies. Issues such as data security, privacy breaches, and the potential misuse of technology raise important questions about the ethical implications of new advancements. It is crucial to address these concerns in order to ensure that technology is used responsibly and for the greater good of society.

Finally, the environmental impact of technology is a growing concern. The production and disposal of electronic devices contribute to e-waste and environmental degradation. Additionally, the energy consumption of technology infrastructure adds to the global carbon footprint. Finding sustainable solutions and minimizing the environmental impact of technology is imperative for a greener and more sustainable future.

In conclusion, while current technologies offer remarkable opportunities and benefits, it is imperative to recognize and address their limitations and challenges. By engaging in discussions about these issues, we can work towards overcoming the barriers and ensuring that technology is used in a responsible and inclusive manner. Only by acknowledging and addressing these limitations can we fully harness the potential of technology for the betterment of society.

Advances in mining techniques have revolutionized the way we extract valuable minerals from the earth. Where once miners had to rely on manual labor and primitive tools, today's mining industry is driven by cutting-edge technology and innovation.

One of the most significant advancements in mining techniques is the use of automated machinery and robotics. These technologies allow for faster and more efficient extraction of minerals, while also reducing the need for human labor in hazardous environments. Remote-controlled drones and sensors are also being used to gather data and monitor mine sites, greatly improving safety and productivity.

In addition to machinery, advancements in drilling and blasting techniques have also transformed the mining industry. High-precision drilling equipment and advanced explosives have made it possible to extract minerals from deeper and more challenging geological formations, increasing the overall supply of precious resources.

Furthermore, the implementation of advanced analytics and data processing software has provided mining companies with valuable insights into their operations. By analyzing large volumes of data, companies can optimize their processes and make more informed decisions, leading to increased productivity and cost efficiencies.

Environmental concerns have also driven innovations in mining techniques, with a focus on sustainable and responsible mining practices. Technologies such as water recycling systems, dust suppression methods, and the use of biodegradable chemicals are being adopted to minimize the environmental impact of mining operations.

Overall, the continuous advancement of mining techniques has not only improved the efficiency and safety of the industry but has also paved the way for a more sustainable and environmentally conscious approach to mining. As technology continues to evolve, we can expect to see even more innovative and efficient methods for extracting valuable minerals from the earth.

Ruthenium is a rare and valuable metal that is used in a variety of industrial applications, including electronics, jewelry, and catalysis. As a result, the demand for ruthenium has been steadily increasing in recent years, leading to a growing interest in the exploration and mining of new ruthenium deposits.

One of the key challenges in identifying potential ruthenium deposits is the metal's scarcity and the often complex geological processes that have led to its formation. However, advancements in exploration techniques have made it possible to identify and assess potential ruthenium deposits with greater accuracy and efficiency than ever before.

One of the most widely used techniques for identifying potential ruthenium deposits is geophysical exploration, which involves using various instruments to measure the physical properties of the earth's surface and subsurface. This can include techniques such as magnetic surveys, which can identify the presence of magnetic minerals associated with ruthenium deposits, and electrical surveys, which can detect the presence of conductive minerals that may indicate the presence of ruthenium-bearing ores.

Another important exploration technique for identifying potential ruthenium deposits is geochemical analysis, which involves analyzing the chemical composition of rock and soil samples to determine the presence of ruthenium and associated minerals. This can involve techniques such as soil sampling and analysis, as well as the use of portable X-ray fluorescence (XRF) and inductively coupled plasma (ICP) spectroscopy to rapidly analyze the elemental composition of samples in the field.

In addition to these traditional exploration techniques, advancements in remote sensing technology have also become an important tool in identifying potential ruthenium deposits. This includes the use of satellite imagery and airborne hyperspectral imaging to identify mineral signatures associated with ruthenium deposits, as well as the use of unmanned aerial vehicles (UAVs) equipped with advanced sensors to survey and map potential exploration areas in greater detail.

Overall, the combination of these exploration techniques has significantly improved the ability to identify and assess potential ruthenium deposits. By leveraging the latest advancements in geophysical, geochemical, and remote sensing technology, exploration companies and mining companies are able to target their efforts more effectively, ultimately leading to the discovery and development of new ruthenium resources to meet the growing demand for this valuable metal.

Mining plays a crucial role in global industrial development, but it also comes with significant environmental and social impacts. As society's demand for minerals and metals continues to grow, the mining industry is under pressure to find innovative solutions to increase efficiency and reduce its environmental footprint. Thankfully, advancements in technology and a shift towards sustainable practices are opening doors for more environmentally friendly mining methods.

One innovative mining method that is gaining traction is automated mining, which utilizes cutting-edge technology such as drones, autonomous vehicles, and advanced sensors to streamline operations and reduce the need for manual labor. By incorporating these technologies, mining companies can increase productivity and safety while minimizing the environmental impact of their operations. For example, autonomous vehicles can navigate rugged terrain more efficiently, leading to reduced fuel consumption and lower emissions.

Furthermore, the adoption of renewable energy sources, such as solar and wind power, is also contributing to the reduction of environmental impact in mining operations. By harnessing renewable energy, mining companies can significantly decrease their reliance on fossil fuels, ultimately decreasing their carbon footprint and mitigating the negative effects of greenhouse gas emissions.

In addition to technological advancements, the development of more sustainable mining methods, such as in-situ mining and biomining, are also helping to minimize environmental disruption. In-situ mining allows for the extraction of minerals without the need to remove large amounts of rock and soil, reducing the disturbance to natural landscapes. Biomining, on the other hand, uses microorganisms to extract metals from low-grade ores, reducing the need for harmful chemicals and minimizing waste production.

Furthermore, the implementation of strict regulations and best practices in mine reclamation and rehabilitation is essential in mitigating the environmental impact of mining. Companies are now held accountable for restoring the land to a state that is as close to its original condition as possible, which includes efforts to promote biodiversity and natural habitat restoration.

As the mining industry continues to evolve, it is clear that innovative mining methods are crucial to increasing efficiency and reducing environmental impact. By embracing technological advancements, sustainable practices, and responsible reclamation efforts, the industry can strive to strike a balance between meeting global mineral demands and preserving the environment for future generations.

Technological Innovations in Extraction Processes have revolutionized the way that industries obtain valuable materials from natural resources. From the mining of precious metals to the extraction of fossil fuels, new technologies have made these processes more efficient, safer, and environmentally friendly.

One of the most significant technological innovations in extraction processes is the use of automation and robotics. These technologies have allowed for the creation of highly efficient and precise extraction processes, reducing the need for manual labor and therefore minimizing the risk of accidents and injuries. Automation and robotics have also improved the speed and accuracy of extraction, resulting in higher yields and lower costs.

Another important technological advancement in extraction processes is the development of advanced chemical and biological extraction methods. These methods use cutting-edge science to break down materials and separate valuable components with a higher level of precision and efficiency than traditional methods. For example, biological extraction processes use enzymes and microorganisms to break down and extract metals from ores, reducing the need for harsh chemicals and decreasing the environmental impact of extraction.

In addition, advancements in data processing and analytics have revolutionized the way extraction processes are monitored and controlled. Through the use of sensors and monitoring systems, companies can collect and analyze data in real-time, allowing for the immediate detection of issues and the adjustment of extraction processes to maximize efficiency and reduce waste.

Furthermore, the development of sustainable extraction technologies has become a major focus in recent years. As concerns about environmental impact and resource depletion continue to grow, companies are investing in technologies that minimize the ecological footprint of extraction processes. This includes the use of renewable energy sources, the implementation of recycling and reuse methods, and the development of new materials that require less energy and resources to extract.

Overall, technological innovations in extraction processes have led to significant improvements in efficiency, safety, and sustainability. As these technologies continue to advance, the extraction of valuable materials will become even more sustainable and less harmful to the environment. This is a promising development for industries that rely on extraction processes and for the planet as a whole.

Ruthenium is a rare and valuable metal that is often found in platinum ores. Its scarcity and high demand make it a valuable commodity in various industries, including electronics, automotive, and medical. However, the extraction of ruthenium from ores has long been a challenging and expensive process.

In recent years, there have been significant breakthroughs in chemical processes for extracting ruthenium from ores. These advancements have the potential to revolutionize the ruthenium mining industry and increase the availability of this precious metal.

One of the most promising breakthroughs is the development of new extraction methods that are more efficient and environmentally friendly. Traditional methods for extracting ruthenium involve complex processes and harsh chemicals, which can be harmful to the environment and costly to implement. However, researchers have been successful in developing novel extraction techniques that are not only more efficient but also significantly reduce the environmental impact of ruthenium mining.

Another major breakthrough in ruthenium extraction is the use of advanced technologies such as molecular and nanoscale approaches. These cutting-edge techniques allow for precise and selective extraction of ruthenium from ores, resulting in higher yields and purity levels. Additionally, the use of these advanced technologies minimizes the amount of waste produced during the extraction process, further contributing to the sustainability of ruthenium mining operations.

Furthermore, there have been advancements in the recycling and reclamation of ruthenium from various industrial by-products and waste materials. This has the potential to further increase the availability of ruthenium while reducing the need for extensive mining operations, ultimately contributing to a more sustainable and responsible supply chain for this valuable metal.

Overall, the recent breakthroughs in chemical processes for extracting ruthenium from ores have the potential to significantly impact the ruthenium mining industry. With more efficient and environmentally friendly extraction methods, as well as advancements in innovative technologies and recycling processes, the availability and accessibility of ruthenium are poised to increase, benefiting various industries and driving further innovation in the use of this valuable metal.

The utilization of advanced equipment and machinery for efficient extraction has revolutionized the way industries and businesses operate. With the advent of modern technology, traditional extraction processes have been significantly improved, allowing for higher productivity, reduced labor costs, and more sustainable practices.

One of the key benefits of advanced equipment and machinery is their ability to extract resources with greater precision and accuracy. This not only results in higher yields but also minimizes waste, making the extraction process more sustainable and environmentally friendly. Additionally, advanced machines are capable of operating in harsh and remote environments, making it possible to extract resources from previously inaccessible areas.

Furthermore, advanced equipment and machinery have the capability to automate the extraction process, reducing the need for manual labor and increasing efficiency. This not only improves the safety of workers by minimizing their exposure to potentially hazardous conditions but also allows for a continuous extraction process without the need for frequent human intervention.

In addition, the use of advanced equipment and machinery in extraction processes allows for real-time monitoring and data collection. This provides valuable insights into the efficiency of the extraction process, allowing for timely adjustments and improvements to be made. This, in turn, leads to higher productivity and cost savings for businesses.

Overall, the utilization of advanced equipment and machinery for efficient extraction has led to significant advancements in the industry. Its ability to improve precision, reduce waste, automate processes, and provide real-time data insights has transformed extraction processes and paved the way for more sustainable and productive practices. As technology continues to advance, the extraction industry can expect to see even more improvements in the efficiency and sustainability of resource extraction.

Automation and robotics are playing a crucial role in the Ruthenium mining industry. As one of the rarest elements in the platinum group metals, Ruthenium is in high demand, making its mining a lucrative business. With the increasing need for efficiency, safety, and cost-effectiveness, companies are turning to automation and robotics to streamline the mining process.

One of the key advantages of automation in Ruthenium mining is the ability to operate in harsh and hazardous environments. Robotic systems can be deployed to navigate and carry out tasks in areas that are unsafe for human workers, such as deep underground or in areas with high concentrations of toxic gases. This not only improves safety for workers but also increases the overall efficiency of the mining operation by accessing areas that would otherwise be inaccessible.

In addition to safety, automation and robotics also contribute to increased productivity in Ruthenium mining. Automated systems can operate 24/7, without the need for breaks or rest, leading to a continuous and efficient production process. This ultimately translates to higher output and reduced operational costs, as companies can produce more Ruthenium with less manpower and resources.

Furthermore, robotics and automation technology can enhance the precision and accuracy of the mining process. Advanced sensors and machine learning algorithms allow robots to identify and extract Ruthenium ore with minimal waste, improving the overall yield of the operation.

Another benefit of incorporating automation and robotics in Ruthenium mining is the reduction of environmental impact. By utilizing robotic systems, companies can minimize the disturbance of natural habitats and reduce the release of harmful emissions associated with traditional mining practices.

Overall, the integration of automation and robotics in Ruthenium mining is revolutionizing the industry by improving safety, increasing productivity, and reducing environmental impact. As technology continues to advance, we can expect to see even more innovative solutions for efficient and sustainable mining of this valuable resource.

The integration of artificial intelligence (AI) for real-time monitoring and decision-making has revolutionized the way businesses and organizations operate. With the ability to process massive amounts of data at lightning speed, AI systems can provide actionable insights and make critical decisions in a fraction of the time it would take a human.

In the realm of real-time monitoring, AI systems can continuously analyze data from various sources such as sensors, cameras, and other IoT devices to detect patterns, anomalies, and potential issues. This allows for early detection of problems and proactive intervention to prevent costly downtime or disruptions. In industries such as manufacturing, energy, and healthcare, AI-driven monitoring systems can optimize operations, improve safety, and enhance overall efficiency.

Furthermore, AI-powered decision-making tools enable organizations to automate routine tasks, optimize processes, and respond rapidly to changing conditions. By using machine learning algorithms to analyze historical data and real-time inputs, AI systems can make predictions, recommend actions, and even execute decisions autonomously. This capability is especially valuable in fast-paced and complex environments where human decision-making may be limited by time constraints or cognitive overload.

From predictive maintenance in industrial settings to dynamic pricing in e-commerce, the integration of AI for real-time monitoring and decision-making has the potential to drive significant cost savings, productivity gains, and competitive advantages. However, it is important to note that effective implementation of AI requires careful consideration of ethical, legal, and privacy implications, as well as ongoing monitoring and validation of AI-generated recommendations.

In conclusion, the integration of AI for real-time monitoring and decision-making represents a major leap forward in harnessing the power of data and technology to drive operational excellence and strategic advantage. As AI continues to evolve and mature, organizations that embrace and leverage its capabilities will be better positioned to thrive in the digital age.

As the global community strives to find solutions to combat climate change and preserve the environment, enhanced environmental sustainability measures have become increasingly important. These measures encompass a wide range of practices and policies aimed at reducing the environmental impact of human activities, promoting conservation, and ensuring the well-being of future generations.

One of the key areas of focus for enhanced environmental sustainability measures is the reduction of greenhouse gas emissions. This can be achieved through the adoption of renewable energy sources, improved energy efficiency, and the implementation of carbon capture and storage technologies. By transitioning away from fossil fuels and investing in clean energy alternatives, countries and industries can significantly reduce their contribution to climate change and air pollution.

In addition to mitigating climate change, enhanced environmental sustainability measures also seek to protect and preserve natural ecosystems and biodiversity. This includes efforts to conserve and restore forests, wetlands, and other natural habitats, as well as the implementation of sustainable land use and agricultural practices. By safeguarding these ecosystems, we can ensure the continued availability of vital resources such as clean water, fertile soil, and a diverse range of plant and animal species.

Furthermore, enhanced environmental sustainability measures aim to minimize waste and promote recycling and circular economy practices. This involves reducing the production of single-use plastics, encouraging the use of recyclable materials, and implementing waste management strategies that prioritize the reuse and repurposing of resources. By adopting a circular economy approach, we can minimize resource extraction and waste generation, and create a more sustainable and efficient system of production and consumption.

Finally, enhanced environmental sustainability measures also seek to promote sustainable urban development and transportation. This can include the expansion of public transit systems, the implementation of green infrastructure such as bike lanes and urban parks, and the adoption of smart city technologies that optimize energy usage and reduce environmental impact. By creating more sustainable and livable cities, we can reduce the carbon footprint of urban populations and improve the overall quality of life for residents.

In conclusion, enhanced environmental sustainability measures are crucial for addressing the pressing environmental challenges facing our planet. By reducing greenhouse gas emissions, protecting natural ecosystems, minimizing waste, and promoting sustainable urban development, we can create a more sustainable and resilient future for generations to come. It is imperative that governments, industries, and individuals take action to implement and support these measures in order to mitigate the impacts of climate change and preserve the environment for future generations.